Engineering Biological Replicas

It’s an age-old idea: to use temporary support systems for building more permanent structures. Experts see the presence of wall sockets at Lascaux as evidence that a scaffold was used over 17,000 years ago for the famous paleolithic cave paintings.

Now imagine a structure infinitely more intricate and complex – and made of materials that promote the growth and functioning of living cells – a scaffold for a human heart.

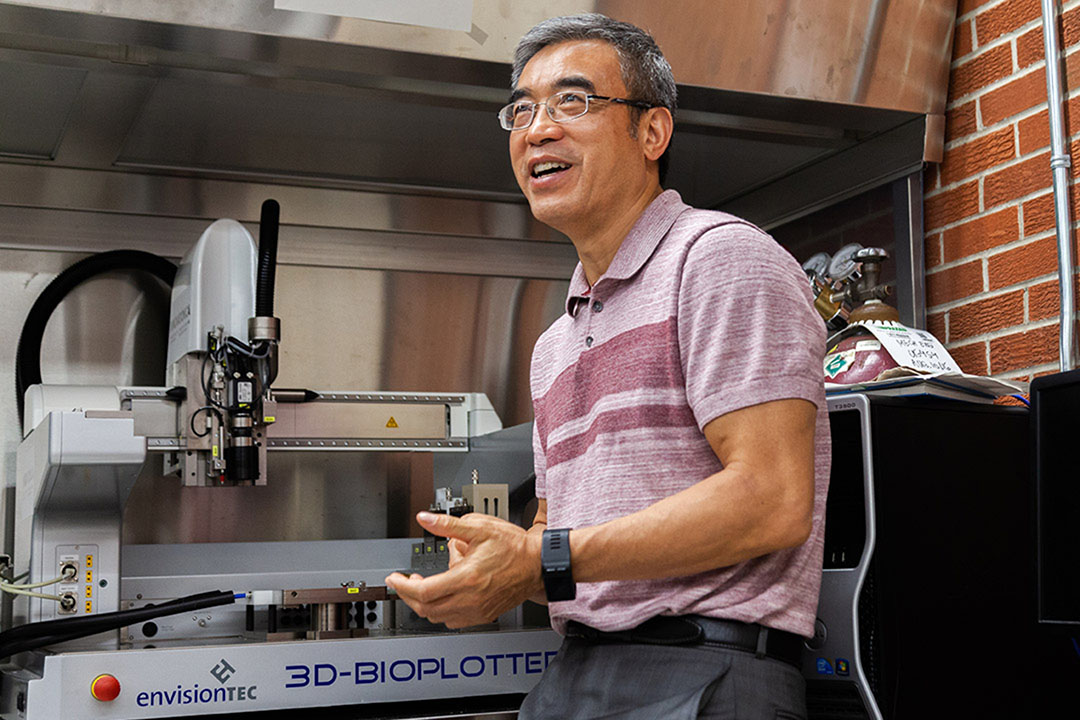

“Millions of people suffer from injuries or damage to organs or tissue, including the heart, cartilage, teeth, bones and nerves,” says Daniel Chen, a mechanical engineering professor in the Department of Biomedical Engineering in the College of Engineering at the University of Saskatchewan (USask). “While transplantation is seen as the gold standard for treating some of these types of injuries, it is a severely restricted option due to limited availability of donor organs or tissue.”

As leader of the Tissue Engineering Research Group, Dr. Chen proposes to improve current treatment approaches by creating tissue and organ substitutes or scaffolds that “incorporate cells harvested from a patient – or another resource – along with growth factors or other biomolecules to stimulate cell growth and functionality.”

These complex systems would be able to perform several functions, such as “enabling and encouraging cell growth and tissue regeneration – as well as facilitate the inflow of nutrients and outflow of metabolic waste,” he says, adding that such scaffolds are designed to degrade gradually during the healing process.

“Success in tissue engineering would mean that someone suffering an injury to an organ or tissue could go to a hospital and have an engineered substitute implanted into her or his body,” says Dr. Chen. “This would allow them to recover the function of a healthy body.”

Research infrastructure supporting innovation

In-depth understanding of the material to be created – including knowledge about external geometries and internal structures – can inform the blueprint for a scaffold that will mimic the architectural, mechanical and biological properties of the tissue or organ to be repaired.

While advances in medical imaging technologies, such as computed tomography and magnetic resonance imaging, have aided understanding of the human body and the architecture of different tissue and organs, Dr. Chen and his team also have access to one-of-a-kind research infrastructure that allows them to investigate materials at the molecular level: the Canadian Light Source (CLS).

Located on university grounds, the CLS is Canada’s only synchrotron facility, says USask President Peter Stoicheff. “Having a facility of this calibre helps us attract researchers and staff who work at the synchrotron – it also brings people here from across the globe to rent beam time.”

At the CLS, 18 beams – or beam lines – are arranged around an oval, along which electrons are accelerated to nearly the speed of light by a combination of radio frequency waves and powerful electromagnets. As the electrons go around the bends, they give off energy in the form of incredibly bright and highly focused light.

Different types of light, primarily infrared and X-ray, are directed along the beam lines to end stations, where researchers conduct specific types of experiments, Stoicheff explains. “Having this amazing lab has created an environment of collaboration that is very global, talented and diverse.”

Laying the foundation for groundbreaking research requires “long-standing commitment and painstaking work,” says Dr. Baljit Singh, vice-president, research at USask. “We had to build up individual components of our research and innovation infrastructure over many decades and operationalize them to achieve the outcomes we want.”

Among the desired impact is to attract “outstanding scholars, who are not only brilliant in their own right but have a mindset for working together across disciplines, facilities and locations,” he says. “So, the question is, ‘Why would somebody want to come to the University of Saskatchewan?’ It comes down to our facilities – and to the very collaborative environment we have cultivated.”

Interdisciplinary collaboration

Cutting-edge research infrastructure like the synchrotron – and its potential for advancing understanding of the molecular makeup of tissue cultures to inform an architecture for tissue engineering – is an important piece of the puzzle for researchers like Dr. Chen, but Dr. Singh emphasizes that it is not the only advantage offered by USask.

“We have 17 schools and colleges that can contribute different expertise to investigations like these,” he says. “There is increased recognition that collaboration is the only way to answer some of today’s most pressing questions. For example, how can we tackle pandemics, injuries or diseases? How can we develop better varieties of crops to withstand climate change? How do we understand polarization in society?”

Complex endeavours like creating a scaffold for a human heart require cross-disciplinary collaboration – and ongoing participation of experts from the life sciences and engineering, says Dr. Chen, whose team is “exploring the development of scaffolds and various scaffold fabrication techniques, including 3D printing such as extrusion-based bioprinting, which uses bioink that contains living organisms with biological relevance for tissue engineering.”

In order to allow a 3D scaffold – created from biomaterials and living cells – to develop into a fully formed organ or tissues, it generally needs “to be cultured in vitro prior to implantation to facilitate its maturation for optimal in-vivo performance or outcomes,” says Dr. Chen.

While in-vitro tests take place in a well-controlled laboratory environment to sustain the viability and function of living cells, for example, through ensuring “sterile and gentle conditions,” he says, “in-vivo testing requires implanting of the material into the living body of an animal or human to determine the extent of negative effects, such as inflammation, on the host system.”

This process is not linear, with insights from each step informing the next, and Dr. Chen says “tissue-engineering at the University of Saskatchewan brings together the CLS, the College of Medicine, the College of Veterinary Medicine and the College of Engineering.”

Accelerating societal impact

The last decade has seen a steady uptick of organ donations in Canada, yet the number of people in need of a transplant has also increased. Although there are more than 2,200 solid organ transplants each year in Canada, on average, 250 people on the waiting list die while waiting for an organ.

By meeting the long-term goal of creating engineered substitutes to be implanted into patients suffering organ damage, Dr. Chen and his team are hoping to make a difference.

In the meantime, there are other promising applications of this work, he says. “Since the scaffolds are created to mimic human tissue or organs, they can also serve as in-vitro tissue or virus-disease models to test or validate newly developed therapeutics and vaccines prior to their use in humans.”

Dr. Singh sees cross-disciplinary endeavours with this kind of potential as proof “that our ecosystem here at the university is working really well.”

In 2023/24, USask achieved significant milestones in attracting $417-million in research grants and over $323-million in research revenues, both amounts exceeding numbers in previous years, he notes. “We find ourselves at the forefront of investigations that focus on some of the big challenges of our time – whether that’s water security, food security or the welfare of the environment, animals and humans – because we’re good at building collaborations and getting things done while staying humble.”

This reputation also allows USask “to attract partners locally and globally, including from academia, governments, industry and the non-profit sector,” says Dr. Singh. “And this brings us to another important question: How do we mobilize all of that for the benefit of the society?”

To mobilize innovation, USask aims to create an environment where researchers can take their idea to impact, including through intellectual property development, technology transfer and enterprise creation, avenues that can be of interest to the Tissue Engineering Research Group.

“Although we have been very successful in building up our research infrastructure and attracting talent, there is always an opportunity to do more,” adds Dr. Singh. “We have to be very intentional about developing our excellence in certain areas of research, scholarly and artistic works, and innovation to meet the needs of communities, both locally and globally.”