From textbooks to hands-on learning

FROM THE DECEMBER 2021 THOROUGH MAGAZINE: Machinist turned mechanical engineering student creates lab kits that bring textbooks to life.

When the team designing the RE-ENGINEERED first-year at USask Engineering was sourcing student lab kits for their new Statics course, they couldn’t find what they wanted.

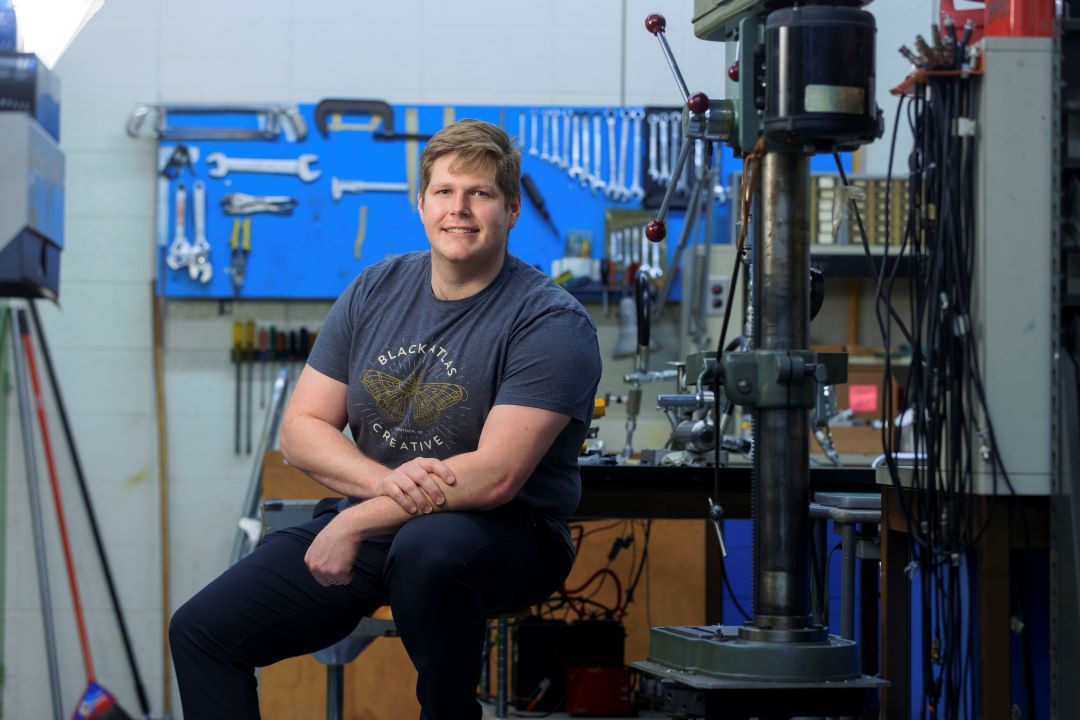

But they knew there was in-house expertise that could help them create what they wanted – they called on third-year mechanical engineering student Dustin Archdekin.

Archdekin, a mature student, had taken an interesting path to engineering. After high school, he went to racing schools and ended up building engines in the States.

“I came back to Canada and I realized that the machining aspect of building race engines was what really drew me into the manufacturing area, so I ended up doing CNC (computer numerical control) machining for about five years.”

After working for a small shop on the USask campus and helping university professors and students with their designs, Archdekin realized he wanted to take his career in a new direction.

“Once I figured out that I really like the design portion, I decided to come back to school after 10 years and go into engineering.”

In his first-year engineering classes he crossed paths with Associate Professor Sean Maw, the Jerry G. Huff Chair in Innovative Teaching, based in the Graham School of Professional Development in the College of Engineering.

Maw is also a co-lead on the team that redesigned first-year engineering at USask. The new program launched in fall 2021.

Archdekin recalls that in Maw’s classes, “I was the guy always asking the questions and then helping other students out in tutorial sessions.”

He and the professor chatted, and Maw learned about Archdekin’s machining and building background, which he sought out when sourcing lab kits for the new first-year Statics course.

“When we were doing the research to look for what we wanted this kit to do, it has never been done, or we couldn't find one that would do a good job of it,” Archdekin said.

“Sean decided to bring me on over the summer to actually create the lab experiments for other students, as a student. I really liked it because I actually got to put my input on how I learned, and then I figured out how maybe other students could learn, too.”

For instance, Archdekin incorporated a tool that tradespeople use into the kit, so that in addition to learning about the concept of a moment of couple – a system of two forces acting in opposite directions – students can feel it as well.

“As well as being able to measure with the torque wrench, we will be able to feel the moment,” Archdekin said. “A couple moment is not generally something that an engineer can feel, and with this kit we are able to feel what a couple moment would feel like.”

Maw is thrilled with the results of Archdekin’s work and the opportunities it brings for student learning.

“Basically, we can bring almost everything in the textbook to life,” he said. “And the students are going to get to play with these lab materials when they want, how they want, so they're going to be able to engage in exploratory learning, which we're very excited about.”

Maw also notes that it was the college’s Engineering Advancement Trust that provided the support to create the kits. “Without partners like the Engineering Advancement Trust believing in the RE-ENGINEERED first year program, opportunities like this just wouldn't exist.”